Adding suitable UV absorbers to packaging materials can enhance the performance stability of the materials, effectively prevent them from aging and discoloring, and thus extend the service life of the packaging materials. In various industries such as food, beverages, pharmaceuticals, and cosmetics, the addition of UV absorbers can protect the products inside the packaging from damage by ultraviolet rays, extend the shelf life, and ensure the quality and safety of the products.

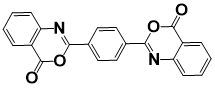

DXSORB®3638 has a high molecular weight, strong absorption efficiency, low volatility, and high thermal stability. Its absorption efficiency is several times that of ordinary UV absorbers. DXSORB®3638 of Danxia New Materials has been registered with the FDA and approved for food contact applications, such as PET bottles and food packaging films. This product requires a low addition amount and does not decompose, precipitate, or migrate during processing and storage, protecting nutrients like vitamins in the contents from losing their nutritional efficacy due to UV exposure.

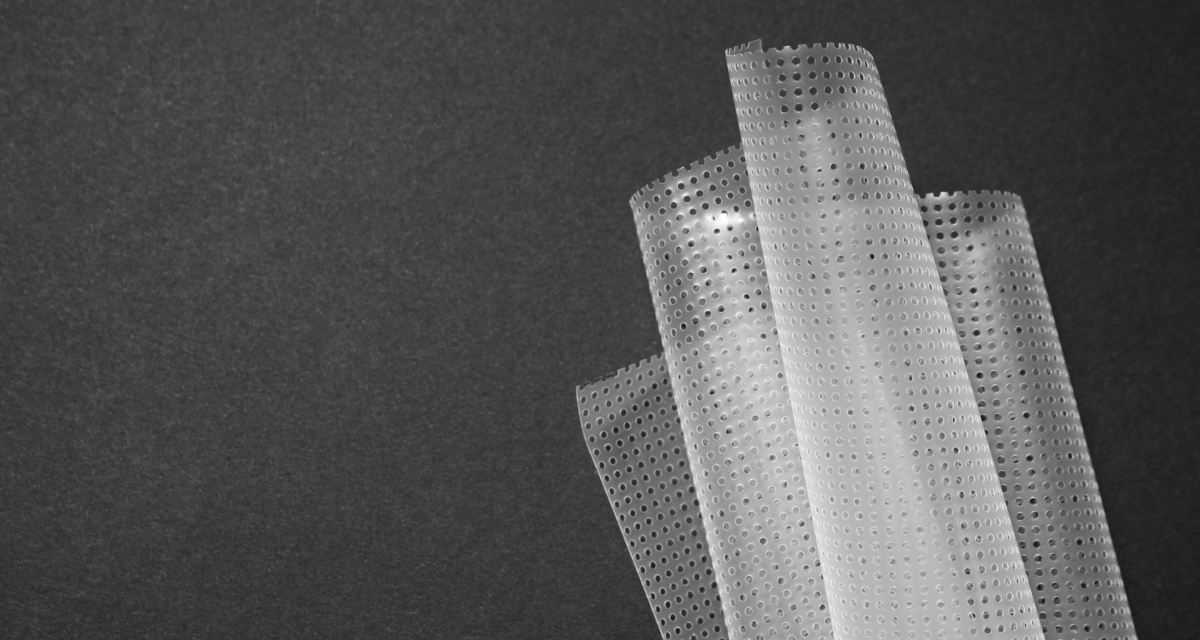

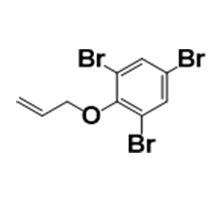

DXSORB®3639 is a widely used liquid polymeric UV absorber suitable for PET packaging materials for food, beverages, milk, and pharmaceuticals. This product can absorb all ultraviolet rays below 390 nm and provide an effective UV barrier, which can greatly extend the shelf life of packaging containers. Traditional UV absorbers must be added in high concentrations, which can cause unnecessary color contamination, migration, precipitation, and odor. DXSORB®3639 is colorless and odorless, has good thermal stability, and is compatible with most common resins. Its uniform liquid appearance allows it to be easily dispersed into resins or machines, ensuring good consistency during the processing and achieving high cost - effectiveness.

Return to List

Return to List