Plastics such as PE, PP, and PA are widely used in daily life as they are lightweight, easy to process, and wear - resistant. However, they also have some drawbacks, such as being prone to heat, flammable, and easy to age, making them unsuitable for use in high - temperature environments. By adding specific additives, the flame - retardant and anti - UV properties of plastics can be improved.

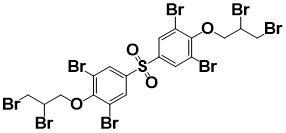

DXFR®920 is a macromolecular additive flame retardant. The flame - retardant effect of this product is better than that of other brominated aromatic flame retardants. It can withstand relatively high processing temperatures and has excellent thermal stability. After addition, it has little impact on the mechanical properties of the material. This type of flame retardant has good compatibility with the matrix resin and shows no precipitation even under harsh conditions. DXFR®920 is mainly used for PP, ABS, etc.

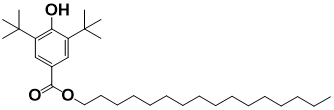

DXSORB®2908 is a UV absorber with wide application adaptability. Its highly efficient light - stabilizing performance can significantly delay the yellowing and embrittlement of polymer materials caused by photo - oxidation. This product has extremely low toxicity and is suitable for fields such as packaging and medical devices. It is widely used in materials such as PP, PE, and PA.

Return to List

Return to List