In photovoltaic and display materials, organic films exposed to sunlight or emission light sources for a long time will undergo photochemical degradation, resulting in a gradual decline in light transmittance and brightness, pixel shrinkage, and damage or malfunction at the device electrode/active layer interface. Adding specific UV absorbers can enable the materials to decompose and transform harmful light during illumination or transmission, thereby protecting the material itself from damage and extending the product's service life. At the same time, UV absorbers can also block UV rays from the light source to protect people's eyes.

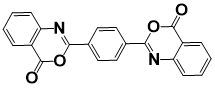

DXSORB®3638 is a benzoxazinone-based UV absorber that can absorb UV rays in the range of 280 - 400 nanometers. It features high temperature resistance, extraction resistance, low volatility, low migration, a wide absorption range, and high absorption efficiency. It is an efficient and non - staining UV absorber. When added to photovoltaic materials, DXSORB®3638 can effectively block the damage of UV rays to battery materials and extend the service life of components. When added to optical films in display materials, such as diffusion films and hardening films, it can prevent them from aging and yellowing, which would affect the display effect, maintain their optical and mechanical properties, and improve the display quality and service life of the films. DXSORB®3638 is especially suitable for transparent PET films, sheets, and plates, as well as transparent PC films, sheets, and plates.

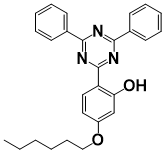

DXSORB®1577 and DXSORB®1164 are conventional triazine - based UV absorbers. After comprehensively comparing various UVA structures, triazine - based UV absorbers have advantages such as high efficiency (less dosage with good effect), low color, good thermal stability, good compatibility, and long light service life, making them a must - choose for long - term weather - resistant applications such as photovoltaic backsheets.

DXSORB®1006 and DXSORB®1009 are enhanced triazine - based UV absorbers. They have extremely high molar absorptivity and can absorb more UV rays under the same dosage condition, thus effectively protecting polymers. Compared with conventional triazine - based UV absorbers, this type of product contains a biphenyl structure, resulting in a higher molecular weight, which gives it excellent high - temperature stability. The 5% TGA thermal decomposition temperature is greater than 400°C (for conventional triazine - based UVA, such as DXSORB®1577, it is 335°C). In photovoltaic backsheets, the thickness of both the adhesive layer and the PET layer is relatively small, so the compatibility between the UV absorber and the resin is also crucial.Both types of UV absorbers have excellent compatibility and will not precipitate even when added in an amount greater than 1%. Among them, DXSORB ® 1006 is recommended for PET layers, DXSORB ® 1009 is recommended for adhesive layers.

DXSORB®1002 is a triazine - based UV absorber especially suitable for PMMA materials. It has a very high absorption capacity in the UV region from 350 to 380 nanometers. It features high heat resistance and low volatility, making it particularly suitable for high - temperature processing of PMMA. UV - 1002 can be widely used in products such as automobile glass, sunglasses, LCD TVs, smartphones, and tablets.

Return to List

Return to List